I-ENG-A® OF ORANGE COUNTY

Professional Forensic Engineering

Product Failure

Product Failure Analysis may involve the investigation of malfunctions or poor design of machinery, consumer products including toys and appliances which caused or could have caused injury or property damage.

In potential products liability losses involving equipment and machinery, the Investigative Engineer will occasionally be asked to ascertain whether the product or equipment contains an “inherent defect”, arising as a consequence of poor design, faulty material, improper assembly or retrofit alteration. Often the equipment did not malfunction, but operator error or poor maintenance caused the accident. This is an important factor which must also be considered.

I-ENG-A has firms which specialize in product design and all members have access to laboratories, researchers and technicians within the network.

Initial Investigations

In analyzing product failures, several important facts must be determined.

- Mode of failure

- Cause of failure

- Determination of how the product was being used at the time of failure

- Determination of similar failures of the same or similar products

- OSHA Regulation Analysis

- Determination of industry standards

- Windstorm Damage Assessment

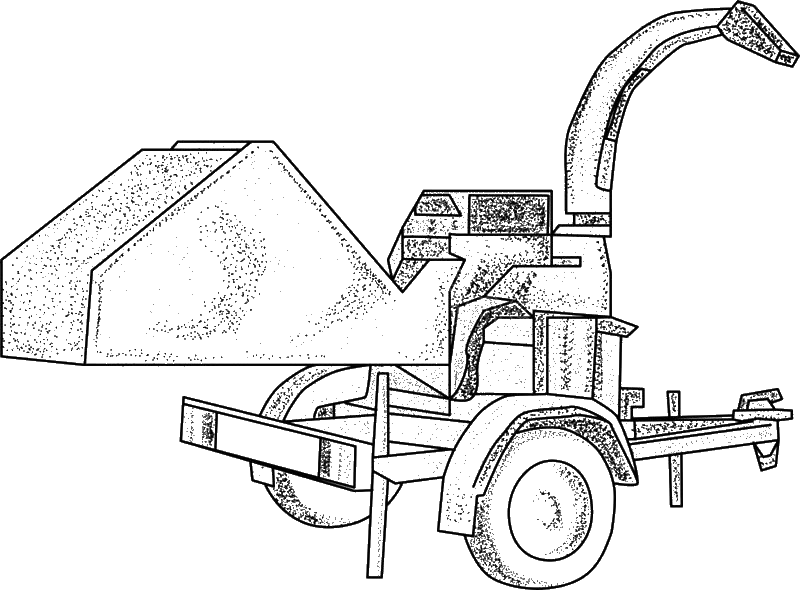

Analysis of Cutting Blade / Wood Chipper Accident

Analysis

Failed products must be carefully inspected; however, affiliates are cautioned not to take possession of any product longer than necessary; to perform only invasive testing only with the prior permission of the client with all parties present; to establish the chain of evidence and to guard against unauthorized access. Products are photographed and may be tested to evaluate:

- Alterations to the product

- Appropriate warnings, instructions and safety alert symbols

- Inherently defective products

- Improper use of the product

Conclusions

I-ENG-A® affiliates offer their clients easily understood written reports stating conclusively the cause-effect relationship surrounding a particular failure